DIN KURV

- No products in the cart.

Subtotal:

€0,00

BEDST SÆLGENDE PRODUKTER

€375,00

€2,93

PCB Forsegling, Radonsikring og Asbest Forsegling | TWO Teknik

TWO Teknik is your partner in all PCB sealing. We ensure that the PCB sealing is a success. We can guarantee and document this with our numerous projects of different types over the past 10 years.

The PCB sealing from TWO Teknik is effective, safe, environmentally friendly, and recognized by the country’s leading advisers.

Every PCB renovation has its own history and recipe for a PCB-free indoor environment. However, all PCB renovations have in common that PCB sealing is involved to a greater or lesser extent, as the remediation of the primary source of PCB contamination alone does not remove the contamination, but only eliminates the cause of contamination (here and now).

PCB gases off and migrates to other surfaces, especially oil-based surfaces such as paint and floor coverings, but can also be detected in, for example, ventilation and furniture, in many cases.

Therefore, the extent of contamination is much greater than just the PCB-containing joints that need to be removed. Today, it is common knowledge that walls and ceilings, even with low concentrations of PCBs, contribute significantly to PCB pollution. These must be addressed in a PCB renovation, and they must be sealed with a product that is both effective and not harmful or toxic – it must be completely natural and self-evident.

Do you need guidance regarding PCBs and PCB sealing?

Then contact a specialist from TWO Teknik.

We are ready to assist you.

+45 72 30 20 31

info@twoteknik.dk

There are several products for PCB sealing available on the Danish market, all of which can seal PCB to a greater or lesser extent. However, no other products offer the same opportunities for user-friendliness, environmental considerations, traceability, and application possibilities as the SPS series. We have been involved from the beginning and have developed our sealing products “first hand” based on the experiences we have gained over more than 10 years. We always develop our products in close dialogue with advisors and contractors, with the greatest consideration for users and the environment. Therefore, all our products are not based on epoxy which (according to the Danish Working Environment Authority – click for link) is harmful and should be limited as epoxy, among other things. Contains carcinogenic substances such as bisphenol A. Our PCB sealing products are extremely effective, innovative, and can be used by all technical personnel.

We believe that our products stand up to comparison at any time. Below, we have collected the common PCB sealing products on the market and compared them based on a range of criteria that we believe are relevant in choosing a product for PCB sealing.

We hope the table can provide an overview and make it easier to choose the right product for the task.

There are several products for PCB sealing available on the Danish market, all of which can seal PCB to a greater or lesser extent. However, no other products offer the same opportunities for user-friendliness, environmental considerations, traceability, and application possibilities as the SPS series. We have been involved from the beginning and have developed our sealing products “first hand” based on the experiences we have gained over more than 10 years. We always develop our products in close dialogue with advisors and contractors, with the greatest consideration for users and the environment. Therefore, all our products are not based on epoxy which (according to the Danish Working Environment Authority – click for link) is harmful and should be limited as epoxy, among other things. Contains carcinogenic substances such as bisphenol A. Our PCB sealing products are extremely effective, innovative, and can be used by all technical personnel.

We believe that our products stand up to comparison at any time. Below, we have collected the common PCB sealing products on the market and compared them based on a range of criteria that we believe are relevant in choosing a product for PCB sealing.

We hope the table can provide an overview and make it easier to choose the right product for the task.

Our PCB sealants SPS Primary and SPS Primary Winter are free of harmful toxins and reduce PCB contamination by over 95%.

Avoid experimenting with untested or products containing harmful substances. We do not use epoxy or products containing bisphenols or solvents when encapsulating PCBs.

Our products are recommended by the country’s leading advisors and are used on all conceivable PCB projects of different sizes.

At TWO Teknik, we recommend that PCB sealing of embedded joints only be used as a temporary solution.

The PCB sealing itself does not remove the cause of contamination, just as the remediation of the actual joint does not in itself remove the PCB contamination.

Although independent laboratory tests show that our PCB sealer reduces pollution by more than 95% of the outgassing for more than 10 years, this solution should be considered temporary. Encapsulation of in-situ PCB joints should only be used as a “here and now” solution to stop PCB outgassing and bring PCB values below the National Board of Health’s threshold values for PCB in indoor air, so that a larger renovation can be properly planned.

PCB sealing as a permanent solution is carried out after thorough decontamination of the PCB-contaminated joints, followed by sealing of the surfaces that have been in direct contact with the PCB-contaminated joint, also known as the secondary sources.

Today, we know that the tertiary sources (all surfaces that have absorbed PCB through the air) contribute to a PCB contamination far more than previously thought. In fact, even low concentrations on large surfaces can create PCB concentrations higher than the Danish Health Authority’s limit values of 300 ng PCB/m3 air. Sealing of the tertiary sources is a very effective method to reduce PCB concentrations in indoor air. The SPS products can be painted over with a quality acrylic paint. TWO Teknik has successfully sealed walls and ceilings in several schools that had been sanitized for PCB joints in the previous years.

If you choose a PCB sealing or encapsulation of the PCB-containing building materials with SPS PRIMÆR, you choose a solution that is economical, manageable, environmentally friendly, and time-efficient compared to other products on the market. We offer both execution of PCB sealing in main and subcontracting, as well as wholesale of PCB sealing.

SPS Primær is also highly suitable for sealing the tertiary surfaces such as walls and ceilings, and can be tinted and subsequently painted over.

Translation: PCB sealing with SPS Primær and SPS Primær Vinter is recognized as encapsulation by experts and advisory specialists, as a safe way to achieve a successful PCB renovation and a PCB-free indoor environment.

We constantly develop and maintain the SPS product line with the products SPS Primær and SPS Primær Vinter, which we have specially developed to encapsulate PCB. At the same time, it is important for us that the PCB sealing is completely free of harmful or toxic substances – such as Epoxy, Isocyanates or solvents. Epoxy contains, among other things, bisphenol-a (BPA) which can be both allergenic and carcinogenic. BPA is also suspected to be endocrine disrupting, can cause reproductive damage, and be a cause of overweight. Read more about the use of epoxy in the AT Guideline on epoxy and isocyanates on the Danish Working Environment Authority’s website here.

We have a very clear attitude towards the environment and the materials we work with. Therefore, our products for PCB sealing are as gentle on people and the environment as possible, and contain none of the harmful substances that are found in Epoxy, for example. With the products in the SPS series, we guarantee an extremely effective encapsulation of PCB, while offering the most environmentally friendly PCB sealer on the market. If sealing PCB-containing surfaces was solely about encapsulating the PCB as much as possible, without any consideration for people and the environment, then different products would be used for the purpose than those used today. However, fortunately, we are increasingly seeing that environmental considerations are important to our customers, and therefore the choice often falls on our products.

Our products are without epoxy and isocyanates – which means that all professionals can work with them, as they do not require an epoxy course or a special certificate. Of course, the products are developed for professionals who already work with PCB. That is, demolition workers, contractors, painters, carpenters, and others. Everything from adhesion, viscosity, and curing time is balanced to function optimally in Nordic climates. It is clear that PCB sealing requires thorough instruction, as the optimal effect of the sealant is contingent on correctly executed work. We offer thorough instruction in the use of all our products, as well as ongoing supervision and final quality control.

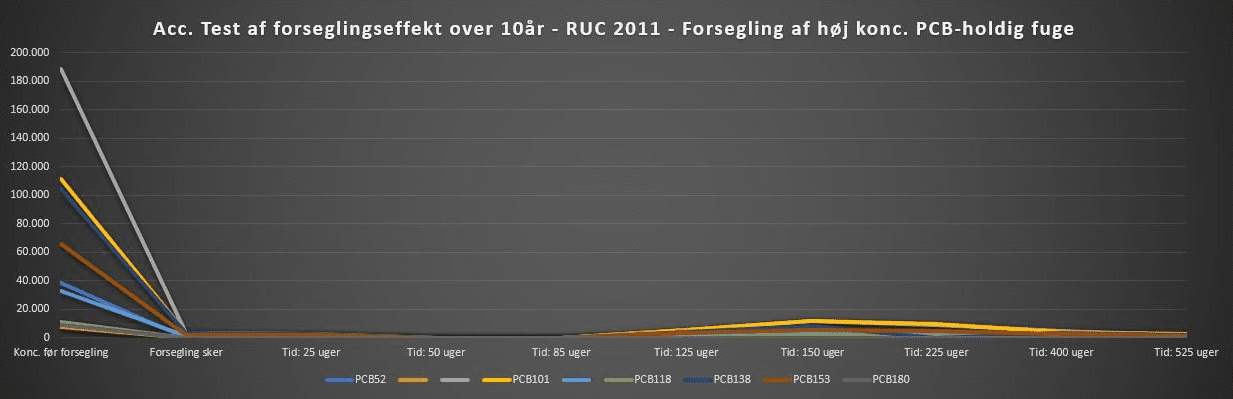

At TWO Teknik, our products have undergone several independent investigations and analyses, including one by Professor John Mortensen from Roskilde University. The analysis of SPS Primær and Primær Vinter demonstrates that our products are highly suitable for sealing PCB, even on surfaces with extremely high levels of off-gassing.

When we have chosen to work with silicates as the basis for our sealing products, it is partly due to the natural formation of an extremely tight “network” or “barriers” by silicates. In addition, silicates do not contain toxic or harmful ingredients. The SPS Primary products form a tighter network than most other sealing products because the silicates in the series form many more internal connections during curing and can also create a chemical connection to, for example, concrete. That is to say, the sealant is not just “glued” to the surface, but comes into contact with the surface material, which provides a much stronger and more durable seal.

The silicates also have the crucial advantage that they do not absorb PCB themselves. This means that the sealed surface itself cannot become a source of pollution. Various products, including acrylic products, actually absorb PCB, and therefore there is typically a sudden drop in concentrations when they are painted. However, over time, this surface will begin to emit PCB and contribute to new pollution.

SPS Primær and Primær Vinter have been tested and further evaluated by Dansk Miljøanalyse, which shows that their barrier properties are over 95%.

If you need guidance regarding PCB sealing, please contact a PCB expert from TWO Teknik.

We have been working with PCB sealing for more than 10 years and are ready to assist you with advice, guidance, and know-how.

Would you like to see our guide to PCB encapsulation?

The SPS Primær series is a Danish product specifically designed for sealing PCBs in building materials. The sealing products contain no harmful or toxic ingredients. Our sealer is the most widely used PCB sealer in the Danish market and has been tested and further developed over the past 10 years.

The SPS Primær series has been diffusion tested by Danish Environmental Analysis and Roskilde University, and tests show barrier properties of over 95%. SPS Primær is available in a regular version for work above 12 degrees Celsius, and a winter version for work between 1 and 12 degrees Celsius.

All professionals can work with the PCB sealants from TWO Teknik, as they do not require an epoxy course or a special certificate, other than thorough instruction that we provide.

Our sealing products have been used in all types of PCB renovation projects throughout the country over the last decade. They are used by the country’s leading contractors and painters, and it is not without reason that they are recommended by the country’s leading advisors in the field.

At the same time, PCB sealants from TWO Teknik can be used by all professionals as they do not require a special course or certificate.

This means that the person working with the actual PCB remediation or, for example, window replacement, can also perform the work with PCB sealing.

The PCB sealing adheres to most surfaces and allows further work after only 24 hours of curing time. SPS Primær can be painted over with most quality paints, and tile adhesive also adheres to the sealing. The winter product cures at just 1 degree Celsius, making it the only PCB sealer in the world to allow sealing even in the winter months.

The sealing is supplied as transparent by default, but can be tinted in desired colors. The tinting can be used to ensure protection against “holidays” and to document the correct number of layers applied for subsequent quality assurance. The tinting can also be used to create a color base for subsequent painting, for example, if a colored wall is to be painted white afterwards, it may be beneficial to have the PCB sealant tinted white.

SPS Primær can be applied with a roller, brush or spray, depending on the task requirements. The correct layer thickness can easily be controlled afterwards with our included layer thickness tool.

You as a builder or consultant can subsequently check whether the layer thickness of the sealing is correct, with ultrasound, and the effect can be verified with our patented tracer Seal Trace – Read more about quality assurance with Seal Trace by clicking below.

As the first in the world, TWO Teknik has produced a product specifically for PCB sealing in cold and Nordic climates. Our SPS Primær Vinter cures at +1 degree Celsius without the use of solvents, epoxy, and isocyanates, which means that all professionals can work with the product and have the assurance that the sealant is not harmful.

SPS Primær Vinter is a further development of the renowned high-tech diffusion barrier SPS Primær, which has already been used in all conceivable PCB renovations throughout the country.

SPS Primary Winter, offers the same very high barrier properties, but cures already at +1 degree Celsius. Thus, SPS Primary Winter offers a much longer and more flexible period for sealing and remediation works, and thus also an improved project economy.

Previously, PCB sealing work was only possible at temperatures above 10 degrees Celsius. Simply because working at lower temperatures has resulted in increased project costs with winter measures, and possibly even delays.

Primary Winter is the only PCB sealer in the world that can be used in the winter months without any additional costs. Primary Winter is just as effective as SPS Primary for sealing and encapsulating PCB. Both products allow for further work after only 24 hours of curing time.

SPS Primær has been diffusion tested by Danish Environmental Analysis, and tests show barrier properties of more than 95%.

Comprehensive remediation of PCB joints or other building materials is generally very expensive in terms of both cost and time. Total renovation after PCB contamination in all materials in a building has a range of follow-up costs. However, with SPS products, we offer a more attractive economy and time for the task, compared to performing a total remediation and re-establishment.

When the joints with PCB have been remediated by an experienced demolition worker, the adjacent surfaces (the secondary PCB-containing surfaces) can be sealed. And already 24 hours after sealing, a new window can be installed, for example, or the sealant can be painted over.

PCB-containing walls and ceilings (the tertiary PCB-containing surfaces) contribute to PCB levels in indoor air to a much greater extent than previously thought. These can be sealed to trap the paint, and already after 24 hours, the sealant can be painted over with a quality paint*. TWO Teknik has extensive experience in successfully fully sealing walls and ceilings, such as at Gasværkvejens School and Årby School.

The price naturally depends on the scope of the task, including whether it is possible to seal PCB-containing joints or surfaces and other building components. Contact TWO Teknik for a non-binding conversation about the project and get a price estimate.

TWO Teknik offers both wholesale sales with detailed guidance and performing PCB sealing in main and subcontracting.

*The selected paint type should always be compatibility tested with the sealant before painting is carried out.

The sealing products from TWO Teknik are among the world’s best products for sealing PCB. They are extremely effective, and no other PCB sealing products offer as flexible options as the SPS series. At the same time, the products are among the most advanced, featuring the world’s only winter sealant, a patented tracer compound called Seal Trace, and many other application options.

The product series is also environmentally friendly and very easy to work with, allowing for quick further work due to its short curing time of only 24 hours.

If you need guidance regarding radon sealing, please contact an expert from TWO Teknik.

We have more than 10 years of experience and are ready to assist you.

If you need guidance regarding radon sealing, please contact an expert from TWO Teknik.

We have more than 10 years of experience and are ready to assist you.

TWO Teknik is Denmark’s first and most experienced company in sealing PCBs in building components.

We have been involved since the beginning, and with our focus on PCBs in indoor environments, we solve a lot of tasks annually in collaboration with contractors and consultants.

We have developed some of the world’s best and most versatile products and solutions for PCBs in building materials. We have been the first in the world with some of them, and we hold patents on others. All of these, as well as our know-how, are available to you as a customer when you choose TWO Teknik as your partner for PCB sealing.

Just as we constantly have our own solutions for evaluation and ongoing development, we also offer to work with new solutions and products externally.

TWO Teknik has a solid collaboration with several major Danish knowledge centers and leading laboratories for testing and development of new products.

No, we produce and sell products and solutions for indoor climate problems, building technical problems, and work environment. We are happy to refer to several of the country's most experienced companies in the field of PCB remediation.

Yes, we perform PCB sealing both as main and subcontractors. If you prefer to do the sealing work yourself, we offer thorough instruction and guidance on the use of all our products.

Yes, you can always call our experts at +45 72302031 or write to info@twoteknik.dk.

For direct building owner advice, we are happy to refer to the country's leading experts in the field.

We use the tracer substance SPS Seal Trace as a unique and comprehensive tool for quality assurance of a PCB sealing. SPS Seal Trace is developed and patented by TWO Teknik.

SPS Seal Trace is a completely unique product that is offered at no additional cost with our products for PCB sealing.

We have a clear stance that our products should be as least harmful as possible for the environment and people. Therefore, none of our products are based on epoxy, which can be allergenic and carcinogenic, and do not contain any isocyanates or solvents of any kind.

At the same time, we do not believe that epoxy is the most appropriate choice for sealing PCB, as epoxy naturally has a limited lifespan as an effective PCB sealer. The requirement for durability or lifespan of products in a building context where there is PCB, is significantly longer than for example the lifespan of a workshop floor where epoxy is normally used.

Anyone who is a professional can work with our products. We offer thorough guidance and instruction on usage, as well as ongoing monitoring and assistance with quality control.

Our sealing products come with layer thickness gauges. These should be used during the sealing work to ensure that the seal has the correct layer thickness of at least 150 µm. We offer thorough guidance and instruction in the use of our products, as well as ongoing monitoring and assistance with quality control.

The layer thickness gauges can be photo documented and included in the quality assurance of the work.

The sealant is typically cured and allows for further work after only 24 hours. This means that, for example, in a window replacement project, windows can be removed, remediated, and sealed on day 1, and new windows can be installed on day 2.

The sealing must be applied in several layers to achieve the correct layer thickness. The sealing is ready for the next layer when the previous layer is "semi-dry", meaning it should not feel sticky but rather like "duct tape". This is usually achieved 30-60 minutes after application. NOTE THAT THE SEALING MUST NOT CURE BETWEEN LAYERS.

The sealant should have a thickness of at least 150um, and the number of layers required to achieve this will depend on the surface being worked on. Normally, 2-3 layers will be sufficient to achieve 150um.

Yes - Both SPS Primær and SPS Primær Vinter can be painted over with most quality acrylic paints. However, tests should always be carried out on a less visible area. (We are always helpful with test stones for paint samples)

YES - We offer both tinting of the sealant and delivery of color powder so that you can do the tinting yourself.